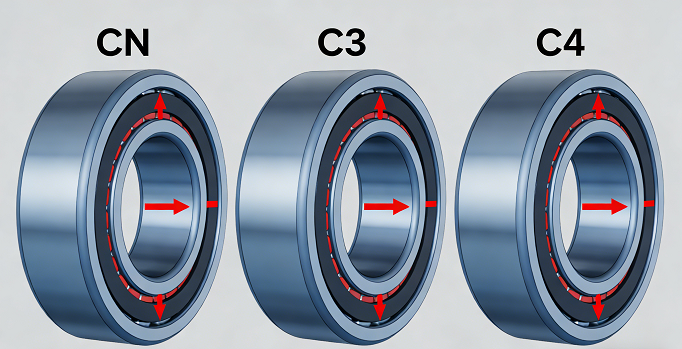

In rolling bearing applications, bearing clearance plays a critical role in determining operating temperature, noise level, load distribution, and overall service life. Bearing clearance refers to the internal space between rolling elements and raceways, allowing relative movement during operation. Selecting the wrong clearance can lead to overheating, vibration, or premature failure. Understanding clearance classes such as CN, C3, and C4 is therefore essential for engineers and maintenance professionals aiming to maximize equipment reliability.

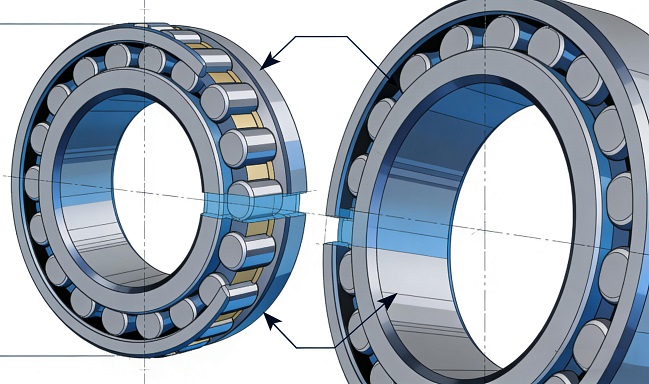

Understanding Radial Clearance

Radial clearance is defined as the total distance that one bearing ring can move radially relative to the other. During installation, this clearance often reduces due to interference fits between the bearing and shaft or housing, as well as thermal expansion during operation. This is why radial clearance must be selected based on real operating conditions rather than catalog values alone.

CN Clearance: Standard for Normal Conditions

CN clearance (also called Normal clearance) is the most commonly used option for standard industrial applications. It is designed for normal operating temperatures, moderate speeds, and standard shaft and housing fits. CN bearings are widely used in electric motors, pumps, fans, and general machinery where thermal expansion and load conditions are predictable. For many applications, CN offers an excellent balance of quiet operation, stability, and long service life.

C3 Clearance: For Higher Temperature Differences

C3 clearance is larger than normal clearance and is suitable for applications where internal clearance is expected to decrease significantly during operation. This often occurs when the inner ring operates at a higher temperature than the outer ring, or when tight interference fits are required. C3 bearings are commonly used in electric motors, gearboxes, compressors, and high-speed machinery, where a certain level of thermal expansion or preload is unavoidable.

C4 Clearance: Extreme Conditions and Heavy Duty Use

C4 clearance is greater than C3 and is intended for demanding environments involving high operating temperatures, heavy loads, or very tight fits. In such conditions, standard clearances would be eliminated quickly, causing excessive heat and early failure. C4 bearings are typically found in steel mills, paper machines, large industrial fans, and other heavy-duty equipment where extreme conditions dominate.

How to Select the Right Clearance

Selecting the correct clearance depends on several factors, including shaft and housing materials, temperature differences between rings, load type, and operating speed. A simplified approach is to use CN for standard conditions, C3 when moderate thermal expansion or preload is expected, and C4 for high-temperature or heavy-load applications. DEMY provides technical support to help customers evaluate these parameters and choose the most suitable clearance for their specific application.

DEMY Bearing Solutions

DEMY manufactures a full range of high-quality bearings available in multiple clearance classes, including CN, C3, and C4. Thanks to advanced grinding accuracy, strict heat treatment control, and consistent quality management, DEMY bearings deliver predictable internal clearances and stable performance. Our engineering team works closely with customers worldwide to ensure optimal bearing selection, helping reduce downtime and extend equipment life.

Post time: Jan-21-2026