Incorrect bearing installation is one of the most common yet preventable causes of premature failure. Industry studies show that up to 16% of bearing failures are directly linked to improper mounting practices. Even a high-quality bearing can suffer reduced service life if installed incorrectly. This guide provides a clear, step-by-step visual approach to proper installation, helping maintenance teams avoid costly mistakes and protect equipment reliability.

Preparation Is the Foundation of Successful Installation (Do)

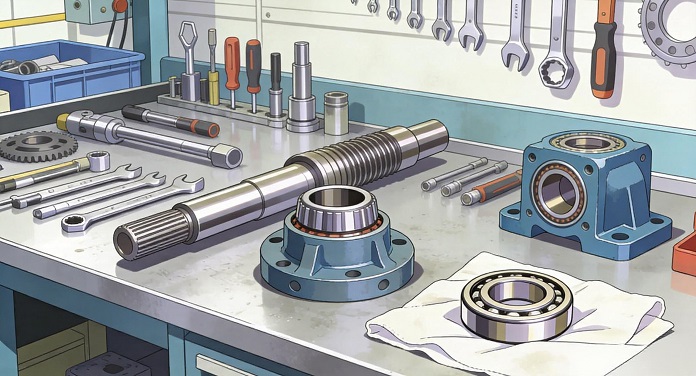

Before installation begins, preparation is critical. The work area should be clean, well-lit, and free from dust or metal particles. All required tools, measuring instruments, and new bearings should be prepared in advance. Shafts and housings must be checked for correct dimensions, roundness, and surface finish, as even minor deviations can cause stress concentrations. Careful preparation ensures stable fits and supports long-term bearing reliability.

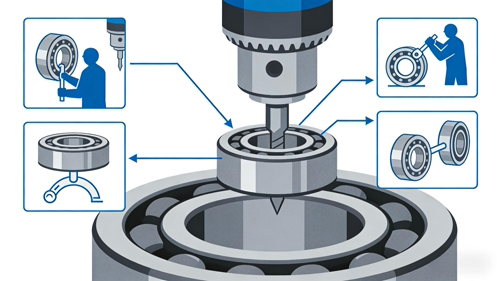

Apply Force Correctly and Evenly (Do)

When mounting a bearing with an interference fit, force must be applied only to the ring that is being press-fitted. For example, when pressing onto a shaft, force should be applied to the inner ring; when pressing into a housing, force should be applied to the outer ring. Specialized sleeves and presses help distribute load evenly and prevent internal damage. Correct force application is essential for maintaining proper bearing mounting integrity.

Use Controlled Heating for Tight Fits (Do)

For larger bearings or tight interference fits, controlled heating can significantly reduce installation force. Induction heaters are the preferred method, as they provide uniform heating and precise temperature control. Bearing temperature should typically not exceed 120°C to avoid altering material properties or reducing hardness. Safe heating practices help ensure smooth installation while protecting bearing material integrity.

Ensure Proper Alignment and Full Seating (Do)

Once mounted, the bearing must sit squarely against the shaft shoulder or housing face with no visible gaps. Misalignment during installation can lead to uneven load distribution and early failure. Gentle rotation by hand after mounting helps confirm smooth operation and correct seating. Accurate positioning supports stable operation and optimal bearing alignment.

Apply Initial Lubrication Immediately (Do)

After installation, the bearing should be lubricated promptly with clean, specified lubricant unless it is pre-lubricated and sealed. Using the correct type and amount of lubricant reduces friction during initial operation and prevents metal-to-metal contact. Proper lubrication from the start plays a key role in long-term bearing lubrication performance.

Avoid Common Installation Mistakes (Don’t)

Never strike the rolling elements or cage directly, as this causes invisible internal damage. Avoid using inappropriate tools such as hammers or chisels, and never apply open flame for heating. Contamination during installation—such as dust, moisture, or metal chips—must be strictly prevented. Eliminating these errors significantly reduces the risk of early bearing failure.

DEMY Support for Correct Installation Practices

DEMY bearings are manufactured with high dimensional accuracy and consistent internal clearance, making proper installation easier and more reliable. In addition to high-quality products, DEMY provides detailed installation guidelines and technical support to help customers achieve optimal results. By combining precision-engineered products with professional guidance, DEMY helps users protect equipment and maximize DEMY bearing performance.

Post time: Jan-05-2026