In recent years, ceramic bearings have emerged as a game – changing technology, disrupting traditional bearing applications across a wide range of industries. These innovative bearings, crafted from advanced ceramic materials, offer a plethora of advantages over their metal counterparts, driving increased efficiency, durability, and performance.

Industry Trends

Growing Demand for High – Performance Bearings

As industries continue to push the boundaries of technology, the demand for bearings that can withstand extreme conditions has skyrocketed. Ceramic bearings, with their exceptional heat resistance, corrosion resistance, and low friction properties, are well – positioned to meet these evolving needs. In the aerospace sector, for example, where every ounce of weight and every bit of efficiency matters, ceramic bearings are being increasingly used in aircraft engines, landing gear, and avionics systems. Their lightweight nature reduces the overall weight of the aircraft, leading to improved fuel efficiency and reduced emissions.

Technological Advancements in Ceramic Materials

The development of new and improved ceramic materials is a key trend in the industry. Manufacturers are constantly researching and experimenting with different compositions to enhance the performance of ceramic bearings. For instance, silicon nitride (Si₃N₄) ceramics have gained significant popularity due to their high strength, excellent thermal shock resistance, and low coefficient of friction. These properties make them ideal for high – speed and high – temperature applications, such as in gas turbines and automotive engines. Additionally, the use of nanotechnology in ceramic manufacturing is enabling the production of bearings with even finer microstructures, further improving their mechanical properties and wear resistance.

Increased Adoption in Emerging Industries

Ceramic bearings are also finding their way into emerging industries, such as renewable energy and medical technology. In the wind energy sector, where bearings are subjected to harsh environmental conditions and high loads, ceramic bearings offer enhanced reliability and longer service life. This reduces the need for frequent maintenance and replacement, resulting in significant cost savings for wind farm operators. In the medical field, ceramic bearings are being used in implantable devices, such as artificial joints and heart pumps, due to their biocompatibility and low wear characteristics. Their use in these applications helps to improve patient outcomes and quality of life.

Use Scenarios

Aerospace Applications

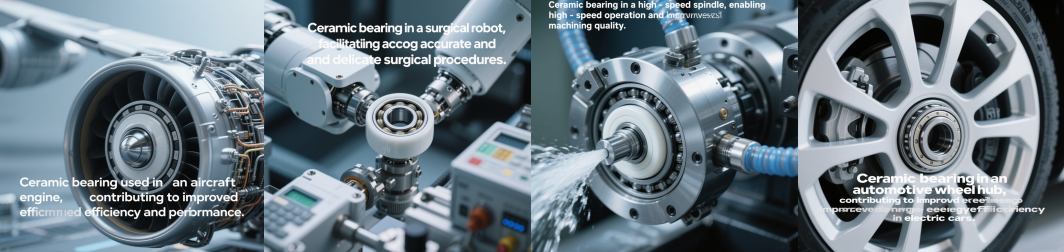

In aircraft engines, ceramic bearings play a crucial role in reducing friction and heat generation. The high – speed rotation of engine components requires bearings that can withstand extreme temperatures and loads. Ceramic bearings, with their low coefficient of friction, enable smoother operation and higher rotational speeds, leading to improved engine efficiency and performance. They are also used in the landing gear systems of aircraft, where their corrosion resistance and high load – carrying capacity are essential for ensuring safe landings. For example, in the wheels of an aircraft, ceramic bearings can handle the high impact forces during touchdown and taxiing while maintaining their integrity.

Medical Equipment

In medical devices, such as MRI machines, surgical robots, and dental drills, precision and reliability are of utmost importance. Ceramic bearings offer the high – precision motion control required in these applications, ensuring accurate and smooth operation. In an MRI machine, for instance, the slightest movement or vibration can affect the quality of the images produced. Ceramic bearings, with their low friction and high rigidity, help to minimize such vibrations, resulting in clearer and more detailed images. In surgical robots, ceramic bearings enable precise and delicate movements, allowing surgeons to perform complex procedures with greater accuracy.

Industrial Machinery

In industrial settings, ceramic bearings are used in a wide variety of machinery, including high – speed spindles, pumps, and compressors. In high – speed spindles, which are commonly used in machining centers and grinding machines, ceramic bearings can operate at much higher speeds than traditional metal bearings. Their high – speed capabilities allow for faster material removal rates and improved surface finish quality. In pumps and compressors, ceramic bearings’ corrosion resistance makes them suitable for handling aggressive fluids and gases. This extends the lifespan of the equipment and reduces maintenance costs.

Automotive Sector

In the automotive industry, ceramic bearings are being increasingly used in high – performance vehicles and electric cars. In high – performance engines, ceramic bearings can reduce friction and improve power transfer, resulting in increased horsepower and torque. They are also used in the wheel hubs of electric cars, where their low rolling resistance helps to improve the vehicle’s energy efficiency and range. Additionally, ceramic bearings’ ability to withstand high temperatures makes them suitable for use in the braking systems of high – performance cars, where they can help to reduce brake fade and improve braking performance.

The Future of Ceramic Bearings

The future looks bright for ceramic bearings, with continued research and development expected to further enhance their performance and expand their applications. As industries strive for greater efficiency, sustainability, and precision, ceramic bearings are likely to play an even more significant role. New materials and manufacturing techniques will be developed, leading to bearings that are even lighter, stronger, and more durable. Moreover, as the cost of ceramic bearings continues to decrease with economies of scale, their adoption is expected to spread across more industries and applications.

In conclusion, ceramic bearings are a remarkable technological advancement that is transforming the way various industries operate. Their unique properties make them an ideal choice for applications where traditional bearings fall short. As the industry trends continue to drive innovation, ceramic bearings are set to become an even more integral part of our technological landscape.

Post time: Jun-30-2025