Introduction A spherical plain bearing looks simple at first glance: rounded inner ring, outer ring, and a smooth sliding surface. But the alphanumeric designation stamped on the side often hides critical information—load capacity, material, internal clearance, and mounting hints. This product brief decodes those clues so you can specify the right bearing faster and with more confidence.

What the Code Really Means Most spherical plain bearing part numbers follow an industry pattern: a prefix for

type, a numeric series for size, and suffixes for material or design tweaks.

For example:

• Prefix (GE, GEG, GEH): indicates housing type and whether it’s flanged or extended.

• Numeric code (e.g., 20, 25, 40): corresponds to bore diameter and series size.

• Suffixes (K, TN, ES): reveal metal cage, PTFE liner, or special corrosion-resistant treatment.

Hidden clues to watch for

• Tolerance and fit: Letters like “C” or “V” can mean tighter or looser radial clearance—vital for precision motion or thermal expansion.

• Liner material: “PTFE” or “P” means low-friction polymer; “S” often indicates steel-on-steel sliding surfaces for heavy loads.

• Sealing and lubrication: “Z” or “RS” may indicate rubber seals; “E” or “L” suggest extended lubrication grooves or single-lip seals.

Design benefits decoded

• Load orientation: Spherical plain bearings compensate for misalignment—designations often tell you the maximum angular deviation permitted.

• Dynamic vs. static use: Some suffixes indicate whether the bearing is optimized for oscillating motion (low speed, high angle) or for slow rotation under heavy load.

• Maintenance interval: A code for self-lubricating liners or lubrication grooves translates to lower servicing frequency.

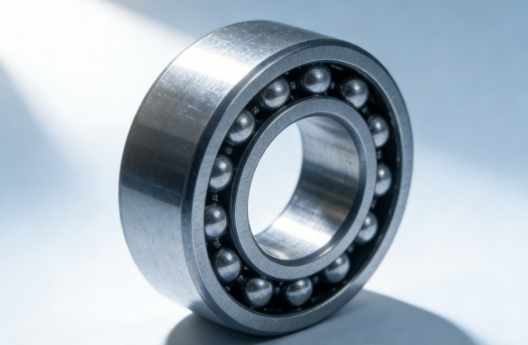

Visual & Material cues (what photos don’t always show)

• Surface finishes: A matte dark finish may imply hardened and coated steel for corrosion resistance; a bright finish often means polished bearing raceways for lower friction.

• Cross-section detail: The presence of a polymer liner, visible in cross-sectional drawings, drastically changes wear characteristics and application suitability.

How to choose — a quick checklist

• Match the prefix: Ensure the bearing type supports your mounting needs (flanged, split, extended).

• Size and load: Use the numeric series to confirm bore and load ratings.

• Material and environment: Select liners or coatings for moisture, chemicals, or extreme temperatures.

• Motion profile: Confirm whether your application is oscillatory or rotational and pick a designation optimized for that regime.

Installation tips from the experts

• Check fit tolerances specified by the designation before pressing in.

• Use proper alignment tools—misalignment beyond the rated angular capacity shortens life.

• Follow lubrication recommendations when suffixes suggest grease grooves or oil channels.

—————————————————————————————————————————————————————————————————————-

Conclusion & Call to Action Designations do more than identify—they communicate engineered choices. Interpreting those hidden clues saves time, reduces failures, and guarantees your machinery performs as intended. Choose bearings with clarity: select the right prefix, confirm size and suffix details, and trust products designed and documented for your environment.

Why choose our bearings? We pair industry-standard designation decoding with rigorous QA, fast lead times, and tailored support to ensure the perfect match for your application. Let our experts help you decode specifications and optimize bearing selection.For a custom quote, technical datasheets, or CAD models, contact our sales team today.

Contact us : NINGBO DEMY (D&M) BEARINGS CO.,LTD

WeChat:18646945620

Whatsapp:+86 18646945620

Zhangting Industrial Zone,Yuyao,China

Post time: Jan-21-2026