Bearings operate at the heart of every machine, and their lifespan directly determines equipment reliability. With proper upkeep, a bearing’s service life can be extended by several times—preventing downtime, cutting repair costs, and protecting critical assets. For facilities aiming to maximize uptime, mastering lubrication and maintenance is essential.

1. Lubricant Selection: Grease vs. Oil

Choosing the right lubricant is the first step toward long-term performance. Grease is ideal for general-purpose, medium-speed applications because it stays in place, provides good sealing, and requires less frequent replenishment. Oil, on the other hand, is preferred for high-speed, high-temperature, or continuously operating systems, since it flows and dissipates heat more effectively. The decision should be based on speed, temperature, load, and operating environment.

2. Proper Lubrication Intervals and Quantity

Both over-lubrication and under-lubrication can destroy a bearing. Excess grease increases friction and heat, while too little lubricant creates metal-to-metal contact. A balanced lubrication schedule must consider speed factor (n × dm), temperature range, bearing size, and load state. High-speed bearings often require smaller, more frequent doses, while slow or heavily loaded bearings need a richer lubricant film. Accurate relubrication guarantees stable film thickness and consistent performance.

3. Maintain Cleanliness: The King of Contamination Control

Contamination remains the number one cause of premature bearing failure. Dust, moisture, fibers, welding spatter, and even fingerprints can dramatically shorten service life. Bearings should always be handled in a clean environment using lint-free gloves and sealed tools. During installation or re-lubrication, avoid open-air exposure and ensure housings and shafts are particle-free. Cleanliness increases reliability more effectively than any other maintenance practice.

4. Ensure Proper Installation and Alignment

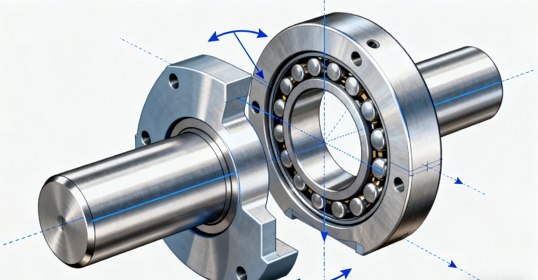

Incorrect installation is another common contributor to early failure. Pressing or hammering a bearing on the wrong race can cause brinelling or internal distortion. Cold mounting with proper arbor presses or hot mounting via induction heaters ensures safe seating. Proper shaft and housing tolerances must be maintained, and alignment should be checked to avoid uneven load distribution. Even minor misalignment can lead to vibration, heat rise, and accelerated wear.

5. Implement Condition Monitoring

Monitoring noise, temperature, and vibration allows maintenance teams to detect early warning signs before catastrophic failure occurs. Handheld tools—such as vibration meters and infrared thermometers—provide quick diagnostics, while advanced systems enable continuous online monitoring. Trending data helps predict wear patterns, detect lubrication film breakdown, and schedule proactive service. Early detection is the foundation of predictive maintenance.

Conclusion: Small Efforts, Big Life Extension

Preventive maintenance costs only a fraction of emergency repairs, and the payoff is enormous. High-quality materials, precise machining, and advanced heat-treatment processes give DEMY bearings a natural advantage in longevity. When paired with proper lubrication, alignment, cleanliness, and monitoring, DEMY products deliver outstanding durability across demanding automotive, industrial, and automation environments.

Post time: Nov-25-2025