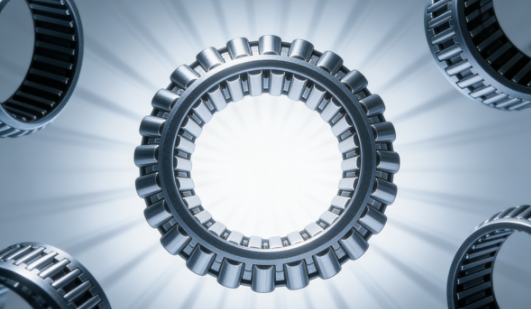

How to Choose Needle Roller Bearings? An Essential Product Guide for Engineers and Buyers

Introduction Needle roller bearings are compact, high-capacity radial bearings that use long, thin rollers to support heavy loads in applications with limited radial space. Their slim profile and excellent load-carrying capability make them ideal for automotive transmissions, gearboxes, compressors, construction equipment, and many industrial drives. Choosing the right needle roller bearing ensures reliability, longer service life, and optimized machine performance.

—————————————————————————————————————————————————————————————————————————————————————————

Key Features and Types

• Full-complement needle bearings: Contain the maximum number of rollers and provide the highest load capacity but have lower speed limits due to greater friction.

• Caged needle bearings: Use cages to space rollers, improving speed capability and reducing friction; suitable for applications with higher rpm.

• Needle roller thrust bearings: Designed for axial loads in limited axial space.

• Combined needle bearings (with inner ring or raceways): Simplify mounting when shaft or housing hardness/finish is inadequate.

How to Choose — Step-by-Step

1. Define the load and load direction

• Determine whether the primary load is radial, axial, or combined. Needle bearings excel at radial loads; for axial or combined loads, consider thrust or combined designs or paired bearings.

2. Consider available radial and axial space

• Needle bearings are best when radial space is limited. Measure shaft and housing dimensions to select bearings that fit without costly redesigns.

3. Determine shaft size and fit

• Choose the bearing with the correct inner diameter to match the shaft tolerance (sliding fit, interference fit). Check whether an inner ring is needed if the shaft surface is not suitable.

4. Evaluate speed and dynamic performance

• High-speed applications benefit from caged needle bearings. Verify the recommended limiting speed and dynamic load ratings from manufacturer catalogs.

5. Lubrication and maintenance requirements

• Decide between grease-lubricated or oil-lubricated systems. Full-complement bearings may retain grease longer but generate more heat at higher speeds. Consider sealed or shielded versions for contamination-prone environments.

6. Temperature and environmental conditions

• For high-temperature or corrosive environments, select bearings made from heat-treated steels, stainless steel, or with special coatings. Pay attention to material compatibility with lubricants.

7. Misalignment and rigidity

• Needle bearings are not tolerant of misalignment. If shaft deflection or misalignment is expected, consider bearings with alignment features or complementary housings, or redesign to reduce misalignment.

8. Life expectancy and load rating calculations

• Use manufacturer L10 life formulas and dynamic load ratings to estimate bearing life under expected conditions. Factor in shock loads and impact duty cycles for a conservative design.

9. Sealing and contamination control

• Select seals or shields where dust, water, or debris are present. Proper sealing dramatically extends bearing service life and reduces maintenance costs.

10. Quality, standards, and supplier support

• Choose bearings that meet ISO/ABMA standards. Work with suppliers who provide detailed datasheets, CAD models, testing certificates, and technical support.

Applications and Practical Tips

• Automotive transmissions: Use caged needle bearings where high rpm and controlled friction are required.

• Gearboxes and reducers: Full-complement bearings handle heavy radial loads in compact gearbox designs.

• Pumps and compressors: Select bearings with appropriate seals and lubrication schemes to resist contamination.

• Assembly and mounting: Ensure correct press-fit procedures, use proper alignment tools, and avoid impact damage to rollers or raceways.

————————————————————————————————————————————————————————————————————————

Why Choose Our Needle Roller Bearings? We offer a comprehensive range of needle roller bearings in full-complement, caged, thrust, and combined configurations, manufactured to strict quality standards and available with custom options. Our engineers assist with bearing selection, life calculations, and mounting guidance to ensure optimal performance for your application.

Call to Action Ready to select the perfect needle roller bearing for your machine? Contact our sales team today for a personalized consultation, competitive quotes, and rapid delivery. Let our experts help you reduce downtime and improve reliability — reach out now to buy high-quality needle roller bearings tailored to your needs.

Post time: Jan-04-2026