In the world of motion, deep groove ball bearings speak a subtle but powerful language — one of precision, resilience, and silent efficiency. These compact components are often overlooked in product catalogs, yet they are the unsung translators between rotary motion and dependable performance. Whether you design motors, conveyors, agricultural machinery, or high-speed household appliances, understanding this hidden language helps you choose bearings that extend life, reduce noise, and maximize uptime.

———————————————————————————————————————————————————————————————-

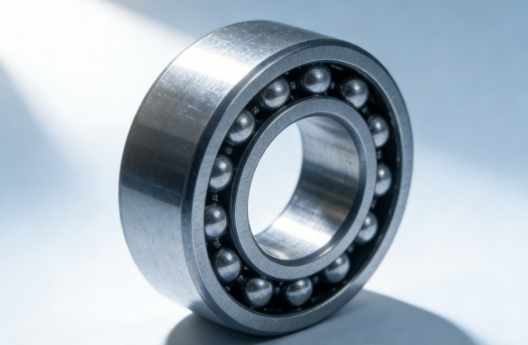

What deep groove ball bearings are?Deep groove ball bearings are single-row, radial bearings characterized by uninterrupted raceways and deep grooves that allow them to support radial loads and limited axial loads in both directions. Their elegant simplicity makes them versatile: they handle high speeds, require minimal maintenance, and offer dependable operation across a wide temperature range.

Why they matter A bearing is more than a part — it is a performance multiplier. Correctly selected deep groove ball bearings:

• Minimize friction and energy loss

• Reduce heat generation and wear

• Maintain alignment under varied loads

• Lessen vibration and acoustic emissions These advantages translate directly into lower operating costs, longer service intervals, and improved product satisfaction.

Key features at a glance

• Deep, uninterrupted raceways for stable ball guidance

• Single-row design for compactness and space efficiency

• High permissible speed thanks to optimized internal geometry

• Ability to accommodate moderate axial loads without complex arrangements

• Available with seals (open, shielded, or fully sealed) to suit contamination and lubrication needs

Materials and precision Performance begins with material selection and manufacturing precision. High-quality deep groove ball bearings typically use high-carbon chromium bearing steel (e.g., SAE 52100) or stainless steel variants for corrosion resistance. Heat treatment and surface finishing yield optimized hardness and fatigue life. Bearings are manufactured to standardized tolerance classes (e.g., ISO, ABEC) to ensure geometric accuracy, concentricity, and smooth rolling behavior — crucial for high-speed or precision applications.

Applications that benefit most Deep groove ball bearings are ubiquitous because of their adaptability. Common applications include:

• Electric motors and generators

• Gearboxes and reducers

• Automotive components (alternators, wheel hubs in some designs)

• Household appliances (washing machines, vacuum cleaners)

• Industrial fans, pumps, and compressors

• Robotic joints and precision actuators

Selecting the right bearing Choosing the ideal deep groove ball bearing involves balancing load, speed, environment, and service life:

• Load and speed: Verify dynamic and static load ratings and permissible RPM

• Environment: Select seals and materials suited to dust, moisture, or chemical exposure

• Lubrication: Decide between grease-filled, oil-lubricated, or pre-lubricated sealed versions

• Precision: Match tolerance class to the application’s sensitivity to runout and vibration

Maintenance and reliability

Routine checks dramatically prolong performance: maintain correct lubrication intervals, monitor operating temperatures, and guard against contamination. Sealed bearings offer low-maintenance solutions for harsh environments, while open or shielded bearings enable relubrication for heavy-duty or long-life applications.

Quality assurance and customization

Our bearing solutions are backed by stringent quality control and testing — dimensional inspections, noise and vibration analysis, and endurance testing. For unique requirements, we offer custom materials, special coatings, modified clearances, and tailored sealing options to meet specific performance goals.

———————————————————————————————————————————————————————————————-

Speak the language of performance Deep groove ball bearings are a small investment with outsized impact on machine reliability and product excellence. If you’re ready to improve efficiency, reduce downtime, and optimize performance, let our experts help you find the perfect bearing solution.Contact us today to discuss your application — professional advice, competitive pricing, and fast delivery await.

Post time: Jan-12-2026