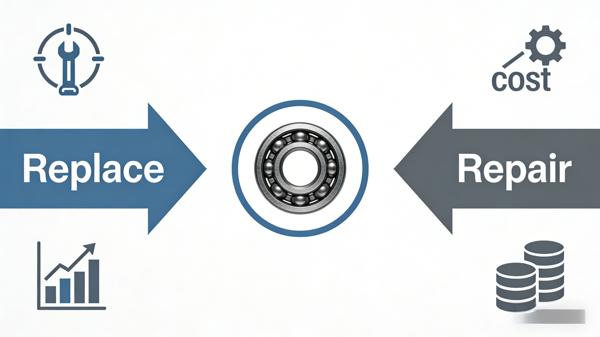

In industrial operations, bearing failure is inevitable—but deciding when to replace vs. repair a bearing is not always straightforward. With limited maintenance budgets, rising downtime costs, and increasing pressure on productivity, maintenance managers must balance short-term savings against long-term reliability. This article provides a practical cost-benefit framework to help you make informed decisions that protect both equipment performance and operating budgets.

When Bearing Replacement Is the Best Choice

In many cases, bearing replacement is the most economical and reliable option. Standard-sized, mass-produced bearings are widely available and relatively inexpensive compared to labor-intensive repairs. Replacement should be strongly considered when bearings show severe wear, spalling, cracking, or heat discoloration—clear signs of structural damage. If the estimated repair cost exceeds 50–60% of the price of a new bearing, replacement almost always delivers better value and lower risk.

Downtime Cost: The Hidden Expense

In high-output industries, equipment downtime often costs far more than the bearing itself. If a failed bearing stops a production line, conveyor system, or automated process, every hour offline can mean lost revenue and missed delivery deadlines. In such scenarios, replacing the bearing with a readily available, high-quality unit allows for rapid recovery and minimizes secondary losses—making replacement the economically smarter decision.

When Bearing Repair Can Be Considered

Bearing repair is typically reserved for large, custom, or long-lead-time bearings where replacement is not immediately feasible. Examples include oversized rolling mill bearings or specialized machinery components. Repair may be viable when damage is minor—such as light surface rust or shallow scratches—and when professional bearing refurbishment services are available. However, repair always carries some uncertainty regarding restored fatigue life.

Understanding Repair Limitations

Even after refurbishment, repaired bearings rarely regain full bearing fatigue life. Grinding or polishing removes surface material, potentially altering internal geometry and load distribution. While repaired bearings may perform adequately in low-risk or non-critical applications, they are generally unsuitable for high-speed, high-load, or safety-critical environments where reliability is essential.

Why New DEMY Bearings Are the Best Long-Term Investment

For the vast majority of industrial applications, installing new DEMY bearings offers the lowest total cost of ownership. DEMY bearings are engineered with premium materials, precision heat treatment, and strict quality control to deliver long service life and predictable performance. Choosing reliable new bearings reduces the risk of repeat failures, protects equipment, and ensures stable long-term operation.

Post time: Dec-16-2025