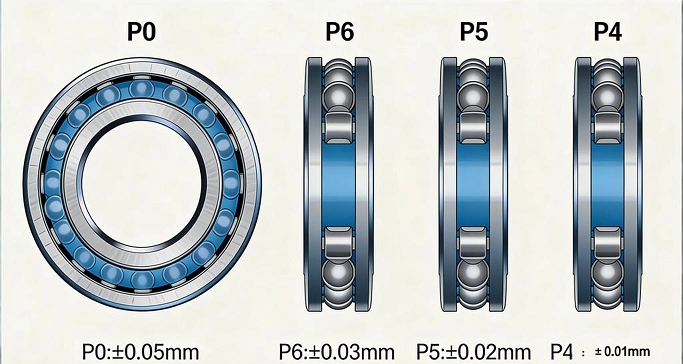

In rolling bearing applications, bearing accuracy classes define the allowable tolerances for dimensions, shape, and rotational precision. These classes directly influence vibration, noise, speed capability, and service life. While many users focus on bearing type or material, accuracy grade is often the deciding factor for high-performance equipment. Understanding what P0, P6, P5, and P4 truly mean helps engineers and buyers select the right bearing without overspending or compromising reliability.

What Do Bearing Accuracy Classes Mean?

Bearing accuracy classes specify tighter limits for bore diameter, outer diameter, radial runout, axial runout, and raceway geometry. Higher accuracy does not simply mean “better,” but rather more controlled manufacturing precision. In practice, installation conditions, shaft quality, and housing accuracy must also match the selected bearing precision grade to achieve real performance benefits.

P0 Accuracy Class: The Standard Choice

P0 bearings represent the normal accuracy class and are the most widely used in industrial applications. They are suitable for general machinery operating at moderate speeds and loads, where ultra-low vibration is not critical. Applications include conveyors, agricultural machinery, pumps, and standard gearboxes. P0 bearings offer excellent cost efficiency and dependable performance for everyday equipment.

P6 Accuracy Class: Enhanced Performance

P6 bearings provide tighter tolerances than P0 and are commonly used in electric motors, automotive transmissions, and industrial reducers. This accuracy level reduces vibration and improves rotational stability, especially at higher speeds. For many modern machines, P6 strikes a practical balance between improved performance and reasonable cost, making it a popular upgrade from standard bearings.

P5 Accuracy Class: Precision Applications

P5 bearings are designed for precision machinery where rotational accuracy and speed stability are critical. Typical applications include machine tool spindles, high-speed motors, and precision gear systems. With lower runout and improved raceway geometry, P5 bearings significantly reduce noise and heat generation, enabling higher rotational speeds and longer fatigue life.

P4 Accuracy Class: Ultra-Precision Demands

P4 bearings belong to the ultra-precision category and are used in advanced machine tools, aerospace systems, and high-end automation equipment. These bearings deliver exceptional rotational accuracy, minimal vibration, and outstanding consistency. However, they require equally precise shafts, housings, and installation processes to fully realize their advantages.

How Accuracy Affects Performance

Higher accuracy classes result in smoother rotation, reduced vibration, lower noise levels, and increased speed limits. They also contribute to improved load distribution across rolling elements, which enhances bearing fatigue life. However, the benefits diminish if the surrounding system lacks matching precision, making correct system-level design essential.

Cost vs. Value: Choosing the Right Class

Selecting the highest accuracy grade is not always the most economical solution. The optimal choice depends on the final equipment requirements—such as machining accuracy, motor efficiency, or operational speed. Over-specifying increases costs unnecessarily, while under-specifying can limit performance. DEMY supports customers by evaluating real operating conditions to recommend the most cost-effective accuracy class.

DEMY Bearing Accuracy Solutions

DEMY manufactures bearings across multiple accuracy classes, from P0 to P5, with strict quality control at every production stage. Advanced grinding technology, stable heat treatment, and comprehensive inspection ensure consistent accuracy and performance. Whether for standard machinery or precision equipment, DEMY provides reliable solutions tailored to each application’s technical and commercial needs.

Post time: Jan-27-2026