Contamination is widely recognized as the number one cause of premature bearing failure, responsible for nearly half of all breakdowns across industrial applications. Dust, moisture, metal debris, chemicals, and even microscopic particles can dramatically shorten a bearing’s usable life. Understanding how contamination damages bearings—and applying targeted prevention strategies—can significantly boost equipment reliability.

1. Abrasive Wear: The First Stage of Destruction

Abrasive wear occurs when hard particles such as dust, sand, or metal fragments enter the bearing and scratch the raceways, cages, or rolling elements. These micro-cuts reduce smooth rolling and create friction that grows exponentially with operation time. Once abrasive wear begins, the rolling elements no longer maintain a clean contact path, causing noise, vibration, and growing surface roughness. Preventing abrasive wear begins with proper seal selection, clean installation, and strict handling practices.

2. Fatigue Failure Accelerated by Contaminants

Fatigue failure, including pitting and spalling, often develops far earlier when contaminants are present. When particles enter the contact zone, they act as localized stress concentrators, disrupting the load distribution and increasing internal stress. This causes micro-cracks that soon propagate into full surface fatigue. Even small dust particles invisible to the eye can drastically cut bearing life, especially in high-load or oscillating applications. Cleanliness and filtration systems are critical for mitigating this failure mode.

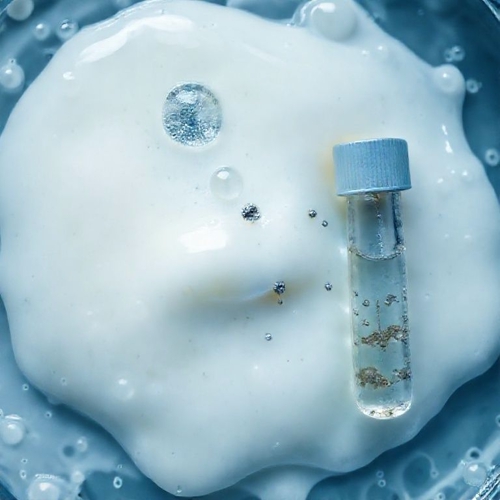

3. Lubricant Degradation: The Silent Killer

Lubrication is essential for preventing metal-to-metal contact, but contamination weakens lubricant performance quickly. Water causes emulsification—turning grease milky—or drastically reducing oil viscosity, while solid contaminants accelerate oxidation and create abrasive slurries. As the lubricant degrades, film thickness collapses, friction increases, and surface temperatures rise. Regular oil sampling, grease inspection, and scheduled replenishment are the best defenses.

Prevention Strategies to Protect Bearing Life

4. Choose the Right Seal Solution

Seals are the first line of defense against contamination. DEMY offers two key sealing solutions:

- Contact seals for low-speed or heavy-load environments requiring strong protection against dust, splashes, and metal debris.

- Non-contact seals for high-speed or high-temperature applications needing low friction and minimal heat generation.

Choosing the correct seal type ensures the bearing remains isolated from harmful contaminants throughout its operating cycle.

5. Improve Overall Equipment Sealing Design

Beyond the bearing itself, the entire system must be properly sealed—including shafts, housings, gaskets, and ventilation paths. Even a high-quality sealed bearing cannot perform reliably if external contamination continuously enters the machinery. Simple improvements like shaft sleeves, proper labyrinth designs, or environmental shields can greatly reduce exposure to dust, coolant, or moisture.

6. Establish Strong Lubrication and Maintenance Procedures

Contamination control is only effective when supported by consistent maintenance practices. This includes:

-

Using clean tools and lint-free gloves

-

Storing bearings in sealed packaging

-

Filtering oil before filling systems

-

Following strict grease-replacement schedules

-

Monitoring noise, temperature, and vibration for early warning signs

When combined, these actions create a contamination-resistant maintenance environment.

Conclusion: Protecting Bearings Is Protecting Your Equipment

Investing in effective contamination control delivers significant returns: fewer breakdowns, longer service life, and reduced operating costs. With advanced sealing solutions, premium materials, and precision manufacturing, DEMY bearings are engineered to maintain performance even in demanding industrial environments. Eliminating contaminants is not just maintenance—it’s reliability insurance.

Post time: Dec-01-2025