Selecting the right bearing materials is one of the most important decisions engineers make when designing reliable machinery. Material properties determine hardness, corrosion resistance, load capacity, fatigue life, and overall performance. This article compares two of the most widely used bearing materials—chrome steel and stainless steel—to help users choose the right option for their application.

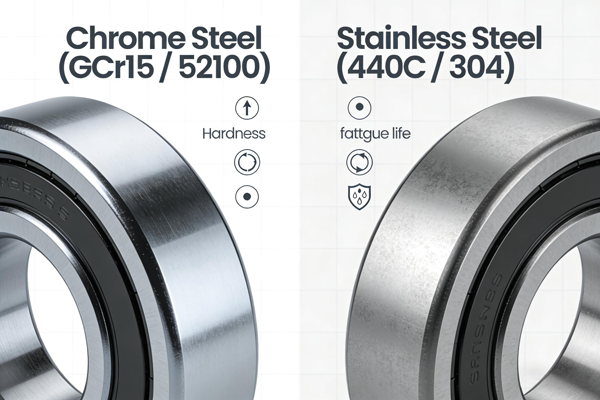

Chrome Steel (GCr15 / SAE 52100)

Chrome steel is the global standard for chrome steel bearings, offering an excellent balance of hardness, load capacity, and cost efficiency. Its high carbon and chromium content allow it to be through-hardened, giving it exceptional wear resistance. These bearings deliver long fatigue life under demanding loads, making them ideal for automotive transmission systems, motors, industrial machinery, and general-purpose equipment. The primary limitation is corrosion: exposure to moisture, chemicals, or humid environments can reduce performance unless proper lubrication and sealing are used.

Stainless Steel (AISI 440C, 304)

Stainless steel is chosen when corrosion resistance is more important than maximum load capacity. Stainless steel bearings made from 440C provide good hardness and moderate fatigue life, while 304 stainless is softer but offers excellent rust resistance. These materials thrive in environments with water, cleaning agents, steam, or chemicals—such as food and beverage processing, pharmaceuticals, medical devices, and marine equipment. Though stainless steel bearings cost more and carry slightly lower fatigue ratings, they significantly outperform chrome steel in harsh environments.

Why 440C Hardness ≠ Chrome Steel Fatigue Life

Although 440C stainless steel can reach hardness levels similar to chrome steel, its bearing fatigue life is typically lower due to microstructural differences. Stainless steel contains more chromium and additional elements that improve corrosion resistance but alter carbide distribution. These carbides are less uniform than those in chrome steel, increasing stress concentrations under repeated loads. As a result, 440C performs well but cannot fully match the long-term fatigue resistance of optimized GCr15/52100.

Application Comparison Table

When making a bearing selection, engineers must balance cost, load capacity, and environmental conditions.

-

Chrome Steel (GCr15/52100): Best for high load, high fatigue life, cost-sensitive applications.

-

Stainless Steel (440C/304): Best for moisture, chemicals, food-grade environments, and marine exposure.

Using the correct material avoids premature wear, corrosion, and unexpected downtime.

DEMY Solutions for Both Materials

DEMY offers a full range of DEMY bearings in both chrome steel and stainless steel, covering deep groove ball bearings, spherical bearings, precision bearings, and custom-engineered solutions. Our team provides technical evaluation based on load, speed, environment, and expected lifespan to ensure every customer receives the optimal material choice. Whether you need maximum fatigue performance or superior corrosion protection, DEMY delivers consistent, high-precision quality backed by ISO/IATF16949 certification and advanced manufacturing.

Post time: Dec-08-2025