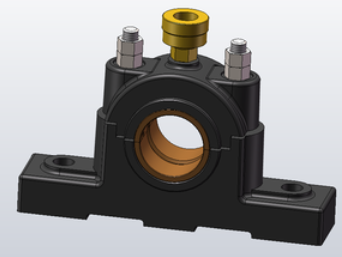

Sliding bearings, also known as plain bearings or bushings, are crucial components in various mechanical systems, providing support and facilitating motion between moving parts. The choice of material for sliding bearings significantly influences their performance, durability, and suitability for specific applications. In this article, we will explore material selection strategies for sliding bearings, compare their performance, and analyze their applications.

————————————————————————————————————————————————————————————————-

1. Understanding Sliding Bearings

Definition:

Sliding bearings are designed to support loads and allow relative motion between surfaces with minimal friction. Unlike rolling bearings, sliding bearings rely on a sliding motion, which can lead to different wear characteristics and performance metrics.

Key Features:

• Load Capacity: Must support both radial and axial loads.

• Friction Coefficient: Lower friction leads to improved efficiency and reduced wear.

• Durability: Should withstand wear, temperature fluctuations, and environmental factors.

2. Common Materials for Sliding Bearings

a. Metallic Materials

i. Bronze Alloys

• Properties: Excellent wear resistance, good machinability, and high load-bearing capacity.

• Applications: Commonly used in automotive and industrial applications, such as engine components and pumps.

ii. Steel

• Properties: High strength and durability, often used in conjunction with surface treatments to enhance wear resistance.

• Applications: Suitable for heavy-duty applications, including construction machinery and heavy vehicles.

b. Polymer Materials

i. PTFE (Polytetrafluoroethylene)

• Properties: Extremely low friction coefficient, excellent chemical resistance, and good thermal stability.

• Applications: Ideal for applications requiring low friction and resistance to harsh chemicals, such as in food processing and pharmaceuticals.

ii. Nylon

• Properties: Lightweight, good wear resistance, and self-lubricating properties.

• Applications: Commonly used in consumer products, automotive components, and machinery where weight reduction is essential.

c. Composite Materials

i. Fiber-Reinforced Composites

• Properties: High strength-to-weight ratio, excellent wear resistance, and low thermal expansion.

• Applications: Used in aerospace and automotive applications where performance and weight savings are critical.

3. Application Analysis

a. Automotive Industry

Sliding bearings are widely used in engines, transmissions, and suspension systems. The choice of material depends on the specific application requirements, such as load capacity and environmental conditions. For example, bronze bearings are often used in engine components due to their excellent wear resistance.

b. Industrial Machinery

In industrial applications, sliding bearings are used in pumps, conveyors, and heavy machinery. Steel bearings are preferred for heavy-duty applications, while polymer bearings are used in environments where corrosion resistance is critical.

c. Aerospace Applications

In aerospace, weight savings and performance are paramount. Fiber-reinforced composites are often selected for their high strength-to-weight ratio and excellent wear resistance, making them ideal for critical components.

————————————————————————————————————————————————————————————————————————————————————————–

4. Conclusion

Selecting the right material for sliding bearings is crucial for optimizing performance and ensuring longevity in various applications. By understanding the properties and advantages of different materials, engineers and manufacturers can make informed decisions that enhance the efficiency and reliability of their systems.

For high-quality sliding bearings tailored to your specific needs, contact us . Let us help you find the perfect bearing solutions to elevate your projects!

Post time: Dec-01-2025