Choosing the right bearing is essential for maximizing equipment performance, extending service life, and reducing maintenance costs. With dozens of bearing types available, understanding how each one behaves under different working conditions is the first step toward reliable machine design.

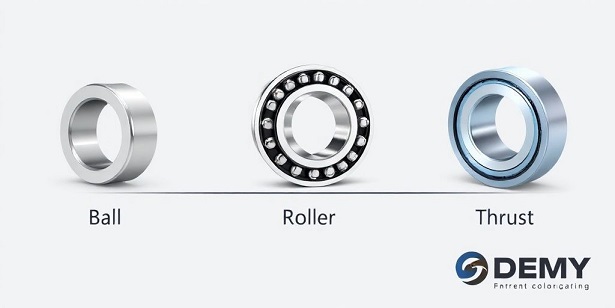

1. Identify Load Type and Direction

Start by determining whether your application experiences radial, axial, or combined loads. For example, deep groove ball bearings are ideal for primarily radial loads with light axial support, while thrust bearings are designed for pure axial forces. For heavy combined loads, spherical roller bearings provide strong load-carrying capacity and durability.

2. Assess Operating Speed

Speed capability is another critical consideration. Ball bearings typically support higher rotational speeds thanks to reduced friction between rolling elements. Roller bearings, on the other hand, are better suited for medium-speed, heavy-load applications. Knowing your machine’s RPM range will help you avoid overheating or premature wear.

3. Consider Misalignment and Rigidity

Misalignment—whether due to shaft deflection, installation tolerances, or housing distortion—can significantly shorten bearing life. In such conditions, self-aligning bearings such as DEMY’s spherical roller series automatically correct misalignment while maintaining rigidity and smooth operation, especially in demanding industrial environments.

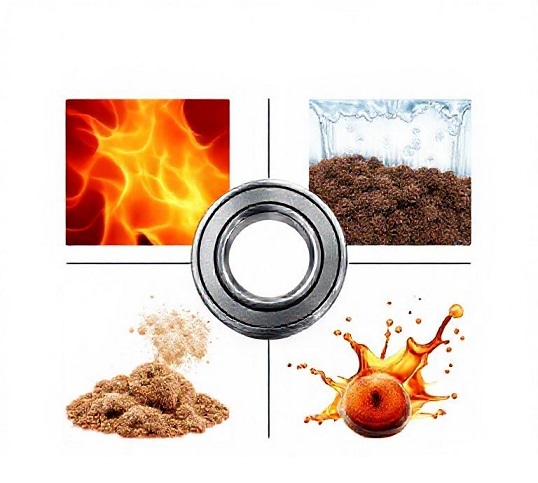

4. Analyze the Operating Environment

Environmental conditions strongly influence bearing performance. High temperatures may require heat-resistant steel or advanced lubrication. Moisture, dust, or chemicals call for stainless steel bearings, ceramic hybrid bearings, or superior sealing options. DEMY offers customized sealing and material configurations to ensure long-term reliability in harsh or contaminated environments.

5. Evaluate Precision and Maintenance Needs

Precision affects rotation accuracy, noise levels, and machine stability. High-precision bearings (such as P5 or P4 grades) are used in motors, robots, or CNC equipment. If low maintenance is a priority, sealed bearings offer excellent performance with minimal lubrication needs, making them ideal for users seeking stable operation without frequent servicing.

Conclusion: A Simplified Selection Flow for Better Decisions

Selecting the right bearing doesn’t need to be complicated. By evaluating load type, speed, installation conditions, environment, and precision requirements, engineers can narrow down options efficiently. For more complex or customized applications, DEMY provides professional technical support, helping customers match the ideal bearing to their machinery for maximum uptime and reliability.

Post time: Nov-18-2025