Rolling bearings are critical components in various machinery and equipment, providing essential support and facilitating smooth motion. However, in extreme environments—such as high temperatures, corrosive atmospheres, or heavy loads—selecting the right bearing becomes crucial for ensuring reliability and longevity. This article explores strategies for selecting and applying rolling bearings in special operating conditions.

1. Understanding Rolling Bearings

Definition:

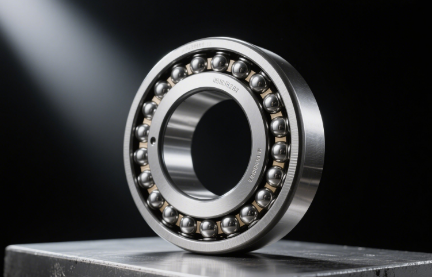

Rolling bearings consist of rolling elements (balls or rollers) and raceways that allow for relative motion between parts while minimizing friction. They are widely used in applications ranging from automotive to aerospace.

Key Features:

• Load Capacity: Capable of supporting both radial and axial loads.

• Durability: Designed to withstand wear and fatigue over time.

• Versatility: Suitable for various applications, including those in extreme conditions.

2. Challenges in Extreme Environments

a. High Temperatures

In applications where temperatures exceed standard operating limits, bearings can experience thermal expansion, lubrication breakdown, and material degradation.

b. Corrosive Conditions

Exposure to chemicals, moisture, or salt can lead to corrosion, significantly reducing the lifespan of standard bearings.

c. Heavy Loads

In heavy-duty applications, bearings must withstand significant forces without failure, requiring careful selection of materials and designs.

d. Contaminants

Dust, dirt, and other contaminants can infiltrate bearings, leading to premature wear and failure.

3. Selection Strategies for Rolling Bearings

a. Material Selection

Choosing the right material is critical for performance in extreme environments. Consider the following options:

• Stainless Steel: Offers excellent corrosion resistance, making it suitable for humid or chemically aggressive environments.

• Ceramic Bearings: Ideal for high-temperature applications due to their ability to withstand extreme heat without degrading.

• Polymer Bearings: Lightweight and resistant to corrosion, these are suitable for applications where weight is a concern.

b. Design Considerations

The design of the bearing can significantly impact its performance:

• Sealed or Shielded Bearings: These designs help protect against contaminants and retain lubrication, extending the bearing’s life in harsh conditions.

• Specialized Geometries: Bearings with modified raceway profiles can better accommodate heavy loads and reduce stress concentrations.

c. Lubrication

Proper lubrication is essential for reducing friction and wear. In extreme environments, consider:

• High-Temperature Greases: Formulated to maintain performance at elevated temperatures.

• Solid Lubricants: Such as graphite or molybdenum disulfide, can be used in environments where liquid lubricants may fail.

4. Application Strategies

a. Regular Maintenance

Implementing a regular maintenance schedule can help identify potential issues before they lead to failure. This includes monitoring lubrication levels and inspecting for signs of wear or contamination.

b. Environmental Controls

Where possible, control the operating environment to minimize exposure to extreme conditions. This may include using protective covers or enclosures.

c. Testing and Validation

Before full-scale implementation, conduct testing under simulated extreme conditions to validate the performance of selected bearings. This can help ensure reliability in actual operating environments.

————————————————————————————————————————————————————————————————————————————————————————-

5. Conclusion

Selecting the right rolling bearings for extreme environments is crucial for ensuring reliable performance and longevity. By understanding the challenges posed by high temperatures, corrosive conditions, heavy loads, and contaminants, and by employing effective selection and application strategies, you can enhance the reliability of your machinery.

For high-quality rolling bearings designed for extreme conditions please contact us . Let us provide you with the perfect bearing solutions to meet your operational needs and ensure optimal performance!

Post time: Dec-15-2025