What are the different types of Deep Groove Ball bearings?

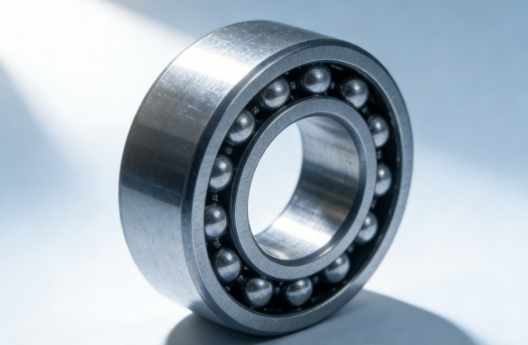

Deep groove ball bearings are among the most versatile and widely used rolling-element bearings in industry. Their simple design—an inner ring, an outer ring, a cage, and balls running in deep raceway grooves—allows them to carry radial loads and moderate axial loads in both directions. They are used in electric motors, pumps, gearboxes, conveyors, household appliances and automotive applications. Because of their adaptability, deep groove ball bearings come in several types and variants tailored to different operating demands: single-row and double-row configurations, open or protected (shielded/sealed) designs, material and coating options, precision grades, and specialized forms such as thin-section or miniature bearings. Each type balances performance factors like speed capacity, load rating, contamination protection, stiffness, and maintenance requirements.

Single-row deep groove ball bearings are the standard and most commonly specified type.

Their compact, low-cost construction supports high rotational speeds with minimal friction and heat generation. These bearings perform well under combined radial and axial loads and are available with various clearances (standard or C3 for extra internal clearance), precision classes (standard, P6, P5), and cage materials (steel, brass, polymer) to suit different environments. Open versions allow relubrication and are ideal when contamination control is managed externally. For general-purpose machinery, the single-row design offers the best compromise between economy, longevity, and performance, making it the default choice for many OEM and aftermarket applications.

Double-row deep groove ball bearings and flavored variants provide higher radial load capacity and improved rigidity compared with single-row types.

Double-row bearings fit applications where space constraints require a single bearing to bear heavier loads or where moment loads and shaft deflection must be minimized. Other construction variants include bearings with flanges or snap rings for axial positioning, and those with reinforced rings to handle misalignment and vibration. These configurations are common in transmission systems, heavy-duty motors, and industrial rollers where service life and stiffness are critical without resorting to larger, more complex bearing types.

Protection and material options expand the utility of deep groove ball bearings across harsh environments.

Shielded (ZZ) and sealed (2RS, RS) bearings prevent ingress of dust and moisture, reducing maintenance and extending service intervals—sealed bearings come pre-lubricated and are effectively maintenance-free in many applications. Material choices include standard chrome steel (AISI 52100) for general use, stainless steel for corrosion resistance in food, medical, or marine contexts, and hybrid bearings with ceramic balls for high-speed or electrically insulated needs. Coatings such as phosphate or black oxide add corrosion resistance and improved running-in characteristics. These choices allow designers to tailor bearings to temperature extremes, wet or corrosive atmospheres, and electrically noisy environments.

Choosing the right type optimizes performance, reduces downtime, and lowers life-cycle cost. For expert help selecting the ideal deep groove ball bearing for your application, contact Global Motion Bearings manufacturer.

Contact Information DEMY Bearings Co., Ltd. Sales & Customer Service:

Kaylin Senior Sales

Cell Phone:+86 18646945620

WeChat:18646945620

Whatsapp:+86 18646945620

We look forward to partnering with you — precision-engineered bearings, global support, unmatched quality.

Post time: Feb-04-2026